-

Posts

492 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

Flat entrance door and building control

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Interesting and difficult in some circumstances. -

Latch maximum dimensions are too restrictive!

Neil Ashdown MAFDI replied to notrub's topic in Fire Doors and Accessories

Contact the door leaf manufacturer's technical department, via the UK agent/distributor (if necessary). They should be able to advise. -

Better to change the door frames to suit the new doors. If that's not possible either order custom made fire doors from a competent supplier or if you have the necessary knowledge, skills and experience you could purchase fire door blanks and fabricate the doors yourself in accordance with it's relevant technical manual.

-

Moving top hinge and making good

Neil Ashdown MAFDI replied to notrub's topic in Fire Doors and Accessories

The door manufacturer is best placed to answer your question. You could make the repairs but will the manufacturer permit this without losing certification? -

Better to change the door frames to suit the new doors. If that's not possible either order custom made fire doors from a competent supplier or if you have the necessary knowledge, skills and experience you could purchase fire door blanks and fabricate the doors yourself in accordance with it's relevant technical manual.

-

The appropriate information would be found in the Building Regulations, where they apply, Approved Document M https://www.gov.uk/government/publications/access-to-and-use-of-buildings-approved-document-m

-

Look for any marks, certification labels, plugs or other signs on the door so that you can trace it to its manufacturer. Then you can obtain the door data sheet or installation instructions and that document will tell you what type of intumescent seals are required and how they should be positioned. If you can't trace back to a manufacturer consult a fire door specialist with all the available information about the doors, so that they can advise appropriately.

-

I must admit, I am now fire door training provider! https://www.firedoorscomplete.com/training-qualification

-

Smoke seals to fire doors are necessary for fire doors opening onto escape routes and in locations where sleeping accommodation exists. Of course there are other areas where they might be necessary too. Consult Annex C of the Building Regulations Approved Document B for information. Compression type batwing seals or those held in a carrier and fitted to the door frame stop might work better.

-

From what you say, this door appears to be a timber-based Nominal Fire Door or Notional Fire Door. That being the case, lipping the top and bottom edges with suitable hardwood and using urea formaldehyde based adhesive would be a suitable repair. Planing the hanging edge by 1mm would also be a suitable repair. An alternative repair for the threshold gap could be to install a threshold plate to the floor, under the door.

-

Because its a Nominal fire door there is no evidence of fire performance for the door. Because their is no evidence there is no way of checking whether or not glazing is permitted and to what specification. Therefore it remains a Nominal Fire Door but check the glass for evidence of fire resistance, such as a mark in the corner of the panel and check that beads, gaskets and fixings appear to be suitable. Always do your utmost to make sure that it really is a nominal fire door and not a certificated or evidenced fire door but with the certification/evidence marks removed or obscured. Also, still carry out an inspection for fire safety order compliance purposes.

-

The 2008 version of BS 8214 would have applied in 2014 and this version also stated that such gaps should of the correct dimensions and sealed with non combustible materials. https://knowledge.bsigroup.com/products/code-of-practice-for-fire-door-assemblies?version=standard

-

Flat entrance door and building control

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Thanks. I will keep digging and if I find anything useful I will post it on here if I can. -

Flat entrance door and building control

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

It seems the Building Safety Regulator might have approached the competent person scheme issue without undertaking due diligence. Have any of the members of the competent person schemes agreed to quote for the work? -

Fire door remedials on a listed building

Neil Ashdown MAFDI replied to Simon Jeffries's topic in Fire Doors and Accessories

https://historicengland.org.uk/images-books/publications/fire-resistance-historic-timber-panel-doors/ -

The document to which you refer is used only as an example of a technical manual for a specific type of door by Falcon Timber https://falcon-timber.com/downloads/ . But you need the manual specific to the door in question.

-

The questions are: 1) Will the door self-close effectively with this type of lock fitted? 2) Will the lock have an adverse effect on the fire resistance performance of the door? Consult the manufacturer of the specific door leaf, where possible, for advice.

-

The document Hardware for Fire & Escape Doors available at http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf contains some very useful information about hinges including Critical Recommendations at section 2.2. The information therein should enable you to decide an appropriate course of action. For metal faced timber-based fire resisting doors it will be necessary to consult the technical manual for the 'specific fire door leaf' to find out what is permitted in terms of fire resistance performance. eg

-

Are specific fire door gaps a legal requirement?

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

The recommendation is 2mm to 4mm. More than 4mm could be an issue affecting the restricted spread of smoke and potentially premature failure of the door in a fire. Less than 2mm could mean that the door fails to self-close and latch correctly (eg. due to binding on a smoke seal), therefore inspect each door to make sure any tight gaps do not affect the ability of the door to self-close completely. -

Old style fire door identification with plugs

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Me too. NickT said the core was circular whereas these have a tree. As NickT said this might be an early forerunner. -

Fire doors in a domestic 3 storey house

Neil Ashdown MAFDI replied to Sean Rowcliffe's topic in Fire Doors and Accessories

Or maybe they refer to the architrave? Table 2 at section 9 of BS 8214: 2016 requires architraves to be 15mm thick in some situations. -

Old style fire door identification with plugs

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Good work. Have never come across a black plug so thanks for sharing. -

Old style fire door identification with plugs

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

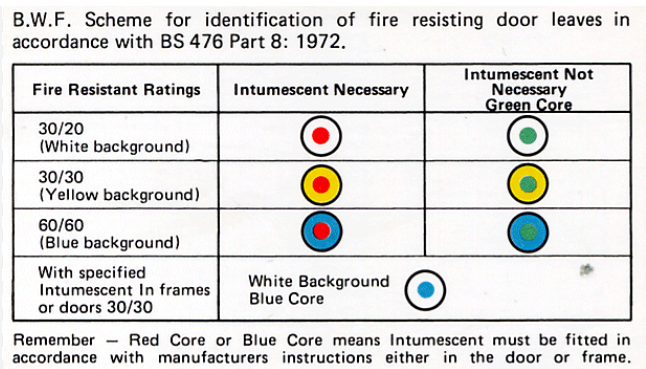

Are you sure it's black and not blue? Blue plug with red centre indicates FD60 with intumescent seals required. -

Interesting. Thank you for posting 🙂