-

Posts

492 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

Flush bolts in doors that have no labels

Neil Ashdown MAFDI replied to FDMan's topic in Fire Doors and Accessories

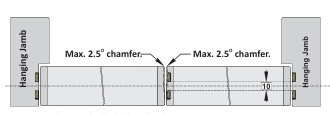

Eg. Active leaf on the right, with seals fitted. Slave leaf on the left with no seals. See below: Consult the product data sheet for the door leaf for specific requirements, if you can. -

Flush bolts in doors that have no labels

Neil Ashdown MAFDI replied to FDMan's topic in Fire Doors and Accessories

The intumescent seals / smoke seals should not be fitted to the same edge as the flush bolt because the interruption of seals would be too great. Fit them instead to the active leaf so that when the doors are closed the seal opposes the bolts. -

Based on much-reading of the differing data for many different types of timber fire door construction, I would opine as follows: 1) Best practice is 6mm min thick lipping after planing-in. So 2mm residual thickness behind the intumescent seal when grooved into the door leaf edge. I have come across assessment reports permitting less than 6mm but I feel that shouldn't be relied on generally. 2) Urea Formaldehyde based adhesive is suitable for adhering hardwood lipping to timber-based FD30 & FD60 doors. 3) Cascamite is widely available from online outlets. PS. Check thickness of door stiles before trimming. There may be no point trimming them down just to fit thicker lipping, if they are already narrow?

-

Former BWF 'Colour-Coded Plug' Scheme

Neil Ashdown MAFDI replied to Pacman's topic in Fire Doors and Accessories

Certainly before 2003, sorry I can't be more precise. More at this thread: -

Yes that's right. Without documentary evidence of fire performance for that type of maglock in that type of door, its up to the Fire Risk Assessor to decide about suitability on a risk-assessed basis.

-

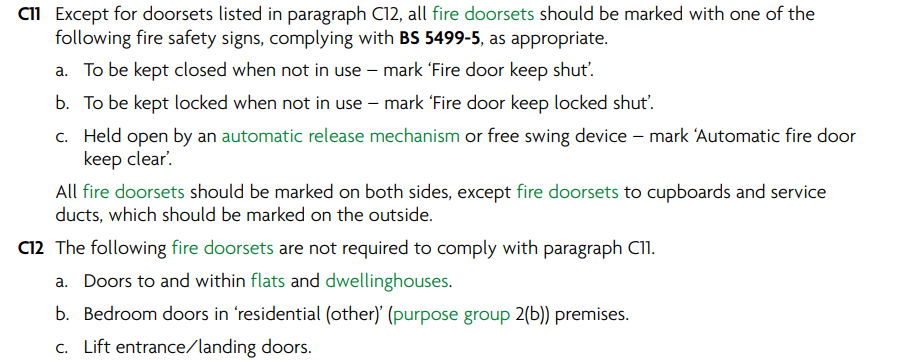

Fire Door Signage on the edge of the door leaf

Neil Ashdown MAFDI replied to davey22's topic in Fire Doors and Accessories

Sign on edge (only) fails to comply with ADB. No doubt about it. -

Fire Door Signage on the edge of the door leaf

Neil Ashdown MAFDI replied to davey22's topic in Fire Doors and Accessories

-

Advice on Repair works to fire doors.

Neil Ashdown MAFDI replied to richardinnorwich's topic in Fire Doors and Accessories

These 'failures' do seem extreme in my opinion and, based on what you have stated above in the case of a timber-based door, I would support the use of a fire rated wood-filler applied in accordance with its product data sheet. -

"I was just under the impression that if this wasn't manufactured and tested this way then the void left by the magnetic locks would be too deep and long to have any suitable repair methods." It may be that the void can be filled with suitable timber and adhesive, or replacement may be necessary. Without seeing the door assembly first-hand, its not possible to say. There are some fire door-set and maglock system combinations that are suitably evidenced. Contact some fire door-set suppliers or ask the fire door inspector for assistance.

-

I would take issue with the company. The frame is already grooved, so clean-out the groove for the seals to fit.

-

The mag-lock appears to interrupt the intumescent seals in the head of the door frame for some distance. If it does, I believe the surveyor is correct to recommend removal and suitable repairs. Ask the surveyor to provide a specification for a compliant repair.

-

If you engage a sufficiently competent fire door inspector/consultant beforehand they will be able to inspect the existing flat entrance door and issue a report on its current compliance status including a list of defects and recommended remedial actions. You can then engage your carpenter to carry out the works or supply and fit a new door on the understanding that payment will be released after sign-off by the competent inspector/consultant. A list of fire door inspectors can be found at https://afdi.org.uk/category/find-a-fire-door-inspector/

-

Is this a fire door?

Neil Ashdown MAFDI replied to Dragos Rusu's topic in Fire Doors and Accessories

Looks like this door in not fire rated. Does it need to be? -

Contact a competent door specialist for an inspection and subsequent remedial works. You could insert suitable hardwood and adhesive to fill those gaps but better to have the door inspected professionally so that you know exactly what type of defects exist and the necessary repairs.

-

Fitting seals to existing fire doors without

Neil Ashdown MAFDI replied to JohnSur's topic in Fire Doors and Accessories

First thing to check is that intumescent seals are not already fitted, concealed behind the lipping of the door leaf. Once you've checked that seals are actually required you could remove the door and then router grooves around the top and vertical edges of the door leaf and fit the seals tight and flush within the grooves. Seals are self-adhesive and must be an intimate fit in the groove so you won't need adhesive or pins. Do not mix different types of seal. -

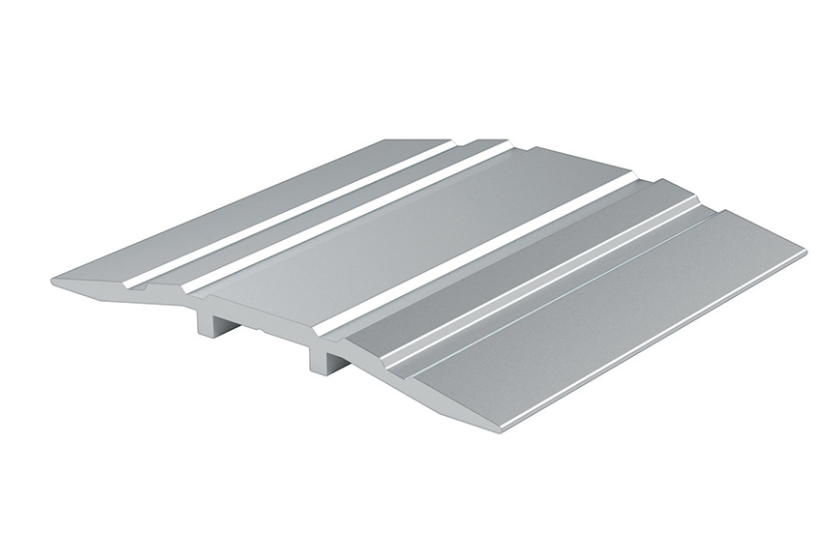

The issues with excessive (more than 10mm) threshold gaps are: 1) that the ultimate fire resistance performance for the door can be compromised because the door can drop further (in a fire attack scenario) to the floor thus opening up a large gap at the top of the door. 2) that the increased flow of air under the door can help to feed the fire thus making it potentially more dangerous 3) that an increased spread of smoke under the door could reach sleeping accommodation and escape routes with potentially highly dangerous consequences. The gap for restricted spread of cold smoke should be 3mm max or it should be closed with a flexible seal, refer to BS 8214: 2016. To resolve these issues, you could fix a suitable hardwood lipping to the door bottom edge and/or fix a threshold plate to the floor. Fit threshold seals where necessary for smoke protection. But first survey each door to decide the most appropriate action.

-

Fixings within a fire door

Neil Ashdown MAFDI replied to Matt 12345's topic in Fire Doors and Accessories

You could remove the seals, insert the fixings and fit new seals. The presence of the existing fixings shouldn't void the door certification, but check with the manufacturer. -

If there is a hole penetrating through the thickness of the timber-based door leaf, then I would make a repair by using tightly fitting hardwood dowel and urea formaldehyde based adhesive.

-

Fixings within a fire door

Neil Ashdown MAFDI replied to Matt 12345's topic in Fire Doors and Accessories

The fire door leaf manufacturer's installation instructions will state the requirements for frame fixings. The seal's don't have to be in the groove behind the seals, but are often fitted at that position because its easier to achieve the 2mm to 4mm perimeter gaps that way. And of course the fixings are concealed once the intumescent seals are installed. You could remove the seals, insert the fixings and fit new seals. -

Fire door full frame

Neil Ashdown MAFDI replied to Dragos Rusu's topic in Fire Doors and Accessories

Noting that the bottom part of the door frame has an intumescent edge seal, I would work on a 2mm to 4mm gap. Have you checked with the door leaf or door-set manufacturer? It would be interesting to see what they require.