-

Posts

492 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

The requirement in BS 8214: 2016 is that the flexible strip seals the gap. No mention of the flooring material.

-

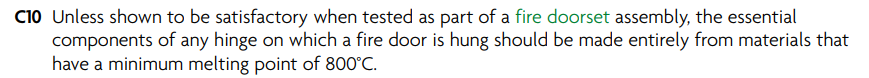

The recommendation is that hinges for fire doors are minimum Grade 11 to BS EN 1935. Most certificated fire doors require that hinges are CE or UKCA marked in accordance with that Standard. Details in the guidance document Code of Practice: Hardware for Fire & Escape Doors. https://www.firecode.org.uk/

-

Answers to your questions: My Q’s are: Q1) Can intumescent strips fix the top and sides? A1) Gaps stated in BS 8214: 2016 Guidance are 2mm to 4mm. So remediate to achieve those gaps and fit suitable seals. Q2) Is the gap at the bottom/threshold acceptable? A2) Threshold gap for a fire door is usually 6mm to 10mm (depending on door manufacturers specification), but if smoke restriction is required the max gap is 3mm as stated in BS 8214: 2016 Guidance . If 3mm cannot be achieved a flexible seal should be fitted to seal the gap.

-

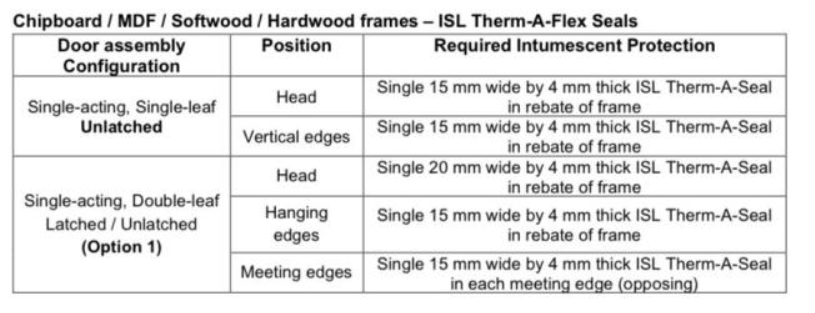

So looking at this. Opposing seals are permitted, so one could be fire only and the other could be fire and smoke.

-

I haven't yet come across a timber fire door that permits opposing intumescent seals, in the meeting edges of double leaves they would be offset rather than directly opposed. Except for doors with edge protectors that is. You could try https://www.ifsa.org.uk/

-

Thanks. Good to know about the Health & Safety (Safety Signs & Signals) Regulations 1996

-

My advice would be to: Establish that the doors are solid core and in suitable condition, record your findings. Add suitable BSEN1154 compliant self-closing devices and make sure all doors self-close completely, reliably, smoothly and without risk of causing a 'trapping injury' - of fingers etc. Add intumescent fire seals and perimeter smoke seals. Make sure the door to frame gaps are between 2mm and 4mm (within reason). Replace the existing letter plate with a fire and smoke rated item and attend to the door threshold so that it will restrict the passage of smoke in a fire. UK Government advice about fire doors can be found at https://www.gov.uk/government/publications/fire-safety-england-regulations-2022-fire-door-guidance/fire-safety-england-regulations-2022-fire-door-guidance

-

I would advise Fire Exit Keep Clear signs on both sides. The existing PUSH sign should be sufficient unless the Fire Risk Assessment requires illuminated signs.

-

Fire doors shutting loudly in HMO below

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Hush pads might affect the smoke seals fitted to fire doors. Its not your door so this might not be any use to you but there are smoke seals that soften the closing action of the door - such as these: -

FD30s intumescent smoke strips

Neil Ashdown MAFDI replied to ELG Paul's topic in Fire Doors and Accessories

The face of intumescent strip should be flush with the surface of the door leaf edge or door frame. So making a deeper groove is not an option. To reduce friction as the door self-closes, you could use alternative smoke seal types such as those with a blade or you could use perimeter seals or seals fitted to the face of the rebate stop. -

Are intumescent seals and smoke seals fitted to the edges of the door leaf? Is the glazed over panel fire rated?

-

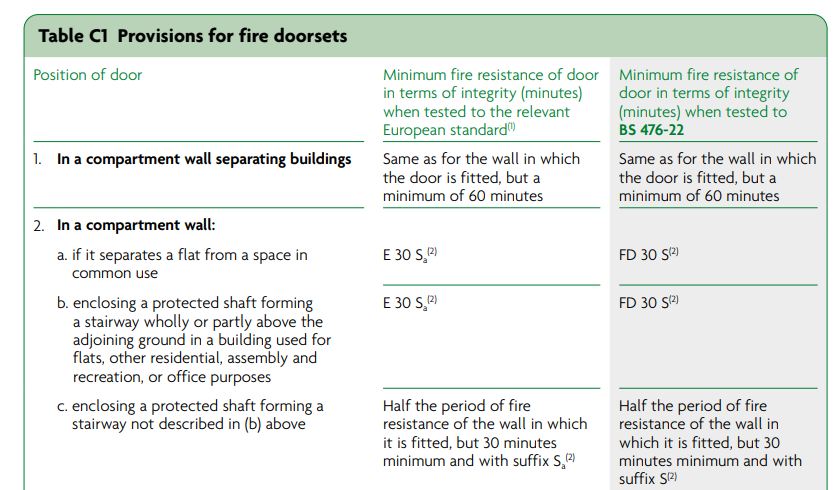

https://assets.publishing.service.gov.uk/media/639ae7e98fa8f5069839c7d7/Approved_Document_B__fire_safety__volume_1_-_Dwellings__2019_edition_incorporating_2020_and_2022_amendments.pdf Appendix C Fire Door-sets. Table C1 2A on page 138 should help. Also this: https://www.gov.uk/government/publications/fire-safety-in-purpose-built-blocks-of-flats

-

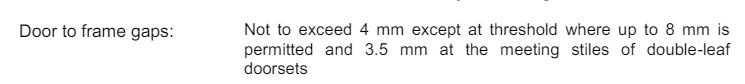

Your situation is shared with many owners of flats in the UK. There is guidance on this matter at https://www.gov.uk/government/publications/fire-safety-in-purpose-built-blocks-of-flats My own opinion, as provided to similar clients, is that you would be wise to engage the services of a carpenter/joiner that has demonstrable competence and experience working with timber-based fire doors. They can inspect the flat entrance door and carry out sensible upgrades to make sure the door self-closes completely and reliably. Also fitting suitable intumescent edge seals & smoke seals, making sure gaps between the door and frame are within the 2mm to 4mm guidance and that the door is aligned with its door frame. There may be other issues but an inspection check by a competent person should reveal these.

-

There are timber fire doors that can have large clear glazed panels. These are a common solution where a larger amount of borrowed light is necessary. eg.

-

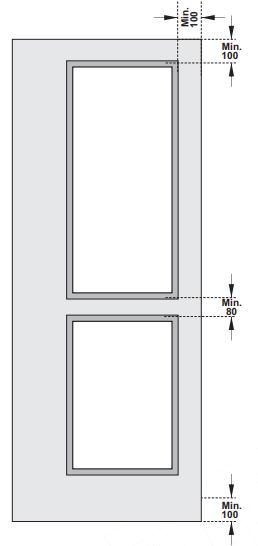

It's not a regulation. HM Gov changes to fire safety regulation has not included any change to perimeter gaps around fire door leaves. The code of practice BS 8214 has recommended a 2mm to 4mm gap since c.1990 - The 2016 version is available at https://knowledge.bsigroup.com/products/timber-based-fire-door-assemblies-code-of-practice?version=standard see section 9.5.2 You could look for marks, labels or a plug on your door to identify the door to it's manufacturer and obtain the certification data sheet. That document would state the gap requirement for compliance with the fire resistance performance certification. eg:

-

Seeking opinions regarding fire door installation

Neil Ashdown MAFDI replied to Zoy3579's topic in Fire Doors and Accessories

The installation should have been completed in accordance with Building Regulations because replacement of fire doors is a notifiable activity and the local building control office should have been informed. The installer should have completed the installation in accordance with the fire resistance performance certification for the products used and installed as well as the relevant Code of Practice BS 8214: 2016. Your task now is to ascertain whether the installer has complied with the above. If they haven't, you have a legitimate reason to make a complaint. -

Its OK to install intumescent and smoke seals to an existing timber-based fire door leaf. But first its important to ensure that concealed intumescents have not been fitted and if they have not then make sure the intumescent seals you fit are the same type as those already fitted at the other edges or in the door frame. For double leaf fire doors, both leaves should be of the same type and evidence of fire performance should be checked where possible.

-

So the installer seems to have made a mistake? The installer should be contacted and remedial works, approved by the door manufacturer, should be carried out. Subject to reasonable acceptance by the client.

-

Old style fire door identification with plugs

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Good information. Thank you. -

Fire door requirements for ground floor flats

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

From what you have said here, I would say the door does not need to be a fire door. The door opens onto an outside area so risk to other building users is virtually nil. However, in some such cases the door may still need to be self-closing fire door with smoke control where there is risk to life because an another property or walkway is located near to or directly above the door. Furthermore, the fact that behind your door is just a staircase (going upwards) lessens the risk to life safety for others considerably. -

This self-closer is not suitable for a fire resistant door. Read the section on door self-closing devices at this document for more information: https://www.firecode.org.uk/

-

From what you have said here, it would seem the door was in poor condition. A fire door should completely and reliably self-close without having to be pushed, so the fact that it failed to do so would suggest that the door was in poor condition.