-

Posts

495 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

Unmarked GWPP in fire door

Neil Ashdown MAFDI replied to Craig's topic in Fire Doors and Accessories

In the DCLG document 'Fire Safety in Purpose Built Blocks of Flats' the author stated that the term 'Notional' refers to a fire door that at the time the building was constructed met the requirements of the regulations. As building regulations are not retrospective there is no requirement to upgrade to modern methods. However, recent product development has meant that fire resistance performance has been improved and that provides us with the opportunity to upgrade existing fire safety measures were such action is worthwhile. So for example, an inspector may recommend that such upgrades be applied in onerous situations such as at sleeping accommodation or on escape routes. -

Does a Final Exit need door closer?

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

A swing free self closer? https://www.safelincs.co.uk/free-swing-door-closers/ -

If you intend to use the fire door inspection report so that contractors can tender for remedial works, its essential that the fire door inspection report contains sufficient information. Many such contractors report that most fire door inspection reports are insufficient for that purpose and insist on carrying out their own inspection before quoting. Make sure you see a sample fire door inspection report before procuring the fire door inspector services.

-

space between fire door frame and opening

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

The fire door will have a fire rating based on a fire resistance performance test on one of its type. Therefore the fire-stopping to the linear gap between the back of the timber door frame and the surrounding wall cannot provide sixty minutes fire resistance for a FD30 fire door assembly. Where the fire door is considered sufficient, seal the linear gap in accordance with the door manufacturers installation instructions or where this is unavailable refer to the Standard BS 8214: 2016 Timber-based fire door assemblies - Code of practice. -

Historic England have published guidance with particular reference to timber-based heritage doors here: https://historicengland.org.uk/images-books/publications/fire-resistance-historic-timber-panel-doors/

-

Thickness for fire door check stops

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Where the fire door is so critical to the fire strategy at the building that it is desirable to upgrade the fire performance of the door. Consider that all timber-based fire doors have had intumescent seals for around the past 30 years now. So why wouldn't you fit them to a fire door? -

Its a manufacturers' plug used by Leaderflush. Contact http://www.leaderflushshapland.co.uk/Contact-Us for more info.

-

Regulation 10: https://www.gov.uk/government/publications/fire-safety-england-regulations-2022/fact-sheet-fire-doors-regulation-10 I would interpret this to mean the 'total height of all storeys combined'.

-

distance between door frame and wall

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Yes 35mm is too big a gap. If using fire foam make sure it complies with the requirements of BS 8214: 2016 Timber-based fire door assemblies - Code of practice. The gap requirement depends on the materials you are using to fill the gap, BS 8214 guidance based on using mineral fibre tightly packed and capped with intumescent acrylic mastic on both sides states 20mm as the maximum gap but refer to the Standard so that you can demonstrate compliance. -

Door closer regulations circa 1998

Neil Ashdown MAFDI replied to Pm790's topic in Fire Doors and Accessories

Building Regulations would have applied to fire doors in 1998 and most likely flat entrance doors would need to have been self-closing at that time. Contact a reputable building regulations consultant for advice. -

Fire doors in a domestic 3 storey house

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Contact an independent building regulations consultant for advice. -

Fire Doors in Metallic Door Frames

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

It depends on the door leaf you use. Consult the technical/certification data sheet for the door leaf and it will tell you the door frame requirements. Stick to that and you can retain product performance certification for the door assembly but if you deviate that, the certification may be void. -

Clearly its impossible to be comprehensive in terms of answers without inspecting the doors, but to answer your questions generally: 1) The corridor double Doors do not close into the frame as I believe there is some air pressure keeping them open. Can the door closer be adjusted to suit or would a more powerful closer be needed. A) Initially check for 'door-binding-issues' and wear and tear or damage with the hinges. Resolve any issues before adjusting the self-closing device. Consult a reputable self-closer manufacturer for advice before procuring a replacement. 2) The disabled toilet door seems to be a fire door as it has seals on edges of the door but it doesn’t self close. (No closer on door) Would this need a door closer? A) If its a toilet, does it need to be a fire door? So check the fire risk assessment for the building. 3) The locks/latches on the timber doors are not CE marked but are marked UL. Are these compliant? A) UL are an American owned fire-testing company so check out this webinar https://www.ul.com/resources/various-safety-standards-fire-door-testing-ul-en-bs and contact the door manufacturer (if that's possible) to see if UL tested/certificated locks or latches are suitable. Also remember, the requirement for CE marking of products (under the scope of harmonised standard BS EN 12209) wasn't a requirement before 1st July 2013. I hope this information is useful.

-

Reducing gaps between door and frame

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

Its my belief that although 'Shapland' are no longer in business, IDSL possess much of the product data and evidence of fire resistance performance. So you could contact them at http://www.leaderflushshapland.co.uk/Integrated-doorsets/Technical-Resources possibly for archived data/information and guidance about the doors. If you wish to use packing material behind hinges this may be done, within reason, using Interdens intumescent sheet material and this is available 1mm and 2mm thick. This sort of information and examples of suitable repairs should be included in the training materials provided. -

Cork has good natural characteristics in terms of fire resistance so it may be that the doors were designed and manufactured as fire doors. However, its not just the core materials and facings that have a bearing of fire resistance. The installation of the door assembly (gaps, voids & alignment), the intumescent edge seals, the smoke seals, the door frame, the ironmongery & hardware, glazing and the fire-stopping around the assembly to the surrounding wall will also matter very much. Therefore, it would be wise to engage a Competent Person to thoroughly inspect the door assembly and provide a fire door inspection report. https://afdi.org.uk/category/find-a-fire-door-inspector/

-

These are dealt with in section 7.3.5 of the document 'Hardware for Fire & Escape Doors: Code of Practice' http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf and typically for a timber-based door the product certification for the door leaf will say, as a general example, something along the lines of:

-

I would make a suitable repair by tightly splicing-in suitable timber to entirely fill the gap.

-

Internal fire doors (Rented flat)

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

I would consult the document https://www.gov.uk/government/publications/fire-safety-in-purpose-built-blocks-of-flats for advice. -

Making good a fire door after cutting into it

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

I would use a urea formaldehyde based adhesive. -

Fire door frame gap advice required

Neil Ashdown MAFDI replied to William Austin's topic in Fire Doors and Accessories

Yes, this is typical of the different types of non-compliance issues that Fire Door Inspectors see on a daily basis. Installation of timber-based fire doors should be in accordance with BS 8214: 2016 Timber-based Fire Door Assemblies: Code of Practice and the door manufacturers product data sheet / installation instructions. -

Fire door frame gap advice required

Neil Ashdown MAFDI replied to William Austin's topic in Fire Doors and Accessories

Q1: BS 8214:2016 only provides directions for gaps with a maximum width of 20mm, many of the gaps between our fire door frame and wall are over 20mm, some being 35mm, is 20mm the maximum gap width permitted ? A) There are some foam products that have been successfully fire tested for use with fire doors at gaps over 20mm. Q2: BS 8214:2016 states in relation to door frame packing that suitable solid packing should be used, ours are hollow plastic, I assume that heat would melt this and given that they are hollow would allow its shape to reduce in size, possibly allowing the door frame to move, are these types of packers valid for use with fire doors? A) The plastic packers should be cut back by at least 10mm and sealed over with intumescent mastic, so that they are encapsulated by the mineral fibre and intumescent mastic system. 3: Two gaps which have a gap width of over 30mm are to be lined with a sheet of plasterboard to reduce the gap width, the information related to the fire door only states that the supporting construction can be lined with soft or hard wood, would a lining of plasterboard be valid? A) Not sure that plasterboard has been fire performance tested in this scenario but have been told that building control would accept this. Personally, I would remove the door frame and screw timber to its back edge, continuous in width and length, to increase the door frame thickness accordingly. Have you informed NHBC, local building control and the builder about these non-compliance issues? -

Cold smoke brush seal gap

Neil Ashdown MAFDI replied to TeeKay's topic in Fire Doors and Accessories

The cold smoke seal should be in contact with the opposing surface in order for it to be effective. There are various types of smoke seals available, including types that can seal against the face of the door instead of at the edge. -

Replacement Fire Doors in Common Areas

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

The fire door inspector should not mandate replacement of doors but they should report any fire door safety issues for the Fire Risk Assessor at the building to advise the Responsible Person about what suitable and sufficient action should be taken. Articles 17 and 38 of the Regulatory Reform (Fire Safety) Order 2005 apply. If the cupboards are located on an escape route or access route and there is a risk of fire within the cupboard it is very likely that the doors would need to be fire doors. Fire doors should be installed and checked for compliance by a Competent Person, Article 18 of the Regulatory Reform (Fire Safety) Order 2005 applies. -

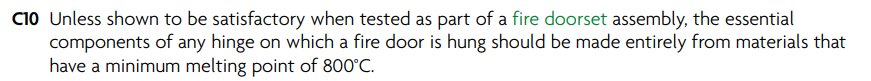

Building regulations in England does not specifically require hinges for fire doors to be EN, BS, CE or UKCA marked but to have a minimum melting point of 800 deg. C. See Appendix C at https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1124736/Approved_Document_B__fire_safety__volume_2_-_Buildings_other_than_dwellings__2019_edition_incorporating_2020_and_2022_amendments.pdf